So, it looks like scientists don’t know what lathe chips look like. I’ve swept up a lot of these offerings to the gods! “Oh thank you, Leblond, lord of the spinning metal, for another good turn. Ooommmmmmmmm….”

Metal chips of the gods;

Tag: Machine Shop

Web Marketing Your Machine Shop

A lot of machinist types don’t really pay attention to their website, I find. Even fairly established shops will have a site, and pretty much forget it exists after it is up. In the modern marketplace, that is a big mistake. There are a lot of potential new customers out on the web, who just might want to drop a bunch of cash on your bench, but you won’t find them if they can’t find you because of your poor web marketing. It goes without saying that main way people shop these days is online. The same goes for industrial clients, as it turns out.

A lot of machinist types don’t really pay attention to their website, I find. Even fairly established shops will have a site, and pretty much forget it exists after it is up. In the modern marketplace, that is a big mistake. There are a lot of potential new customers out on the web, who just might want to drop a bunch of cash on your bench, but you won’t find them if they can’t find you because of your poor web marketing. It goes without saying that main way people shop these days is online. The same goes for industrial clients, as it turns out.

Here is some info from people who are focused on web marketing for industry: Machine Shop Customers First Stop, Your Website When I had my own shop, I found quite a few customers online. Or rather, they found me. Now, it doesn’t have to be super-complicated. A lot can be done with a WordPress blog (like this one). One key is to keep updating (whihc blogs make it easy to do). Keep letting people know all of the cool stuff you are out there doing. Er, in there, in the shop.

MILLING ON CHEVALIER

USING A FORM TOOL ON THE LATHE

I needed to turn some custom parts with a hose barb on one end. This wouldn’t be very hard on a CNC lathe, but I only had a manual lathe. To make a custom shape like this, a form tool is used. This isn’t a technique I invented, obviously. To get my part shape, I had a custom form tool cut by a wire EDM machine at another shop.

To use the tool, I roughed the form close and then plunged the tool in to finish the barb form. It made quite a lot of noise, which might have meant the tool was over center a bit. It was a little hard to set the height. I got the parts done, none the less.

USING TABS TO MACHINE A FLAT PART

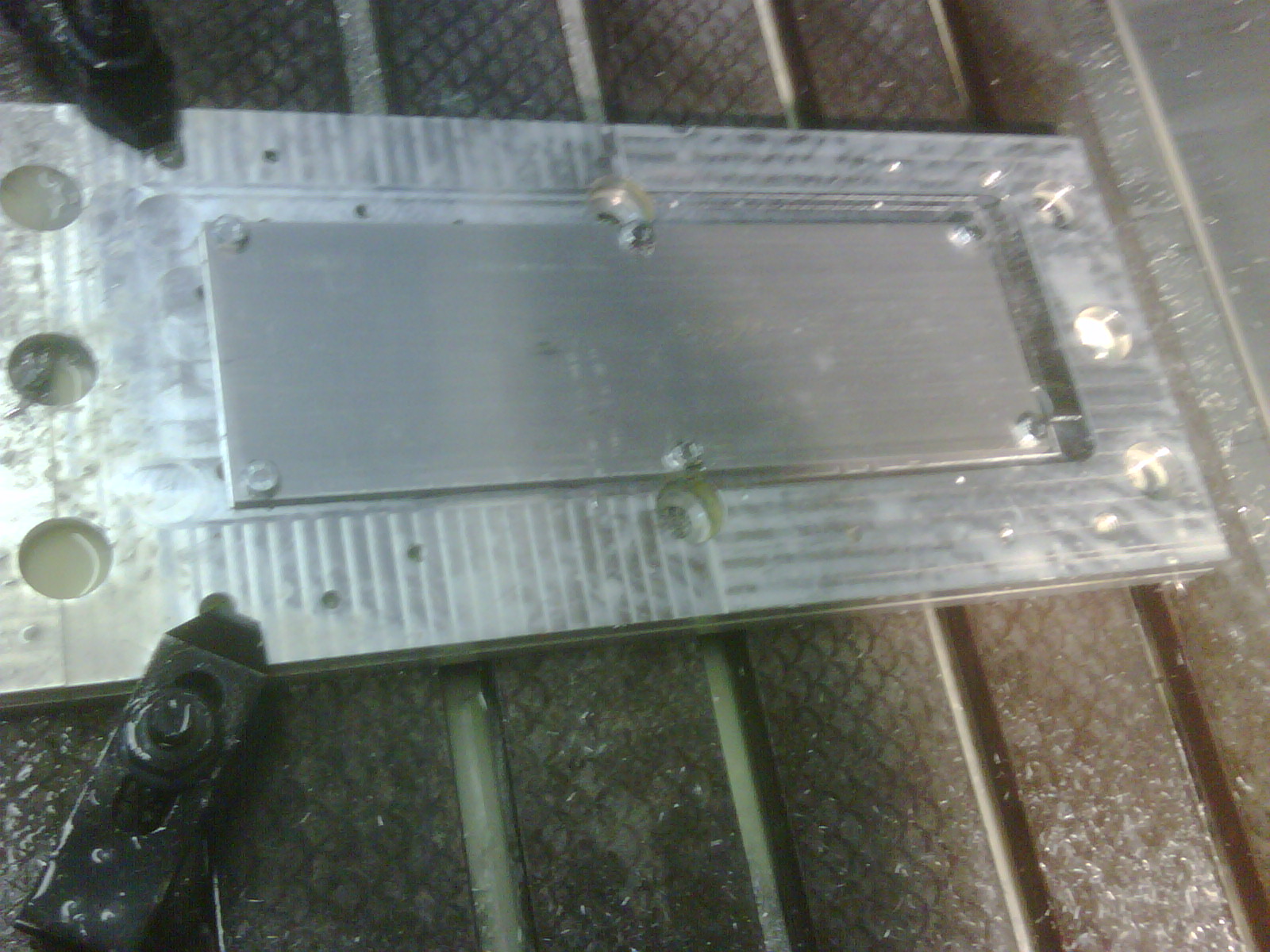

The first thing a machinist asks when making a part is, “how do I hold it?” A lot of times a vise or collet chuck is a good answer. There are a lot of techniques. For holding a flat part, often a good answer is to bolt the part to the table or a surface plate. There are a variety of ways to hold a part down, of course. This is an example of one method for holding a flat part for CNC machining. The technique here is more in using my CAM system to make tabs to retain a fully contoured part.

I needed to make some flat manifold plates for a customer. These were to be CNC milled out of 1/4 inch aluminum. The first step was to determine how they were to be held in my CNC. The problem here is that the parts need to be profiled inside and out, making vise clamping or the like unfeasible. As the parts do have bolt holes in them, I could have held the material down with clamps and then pre-drilled the bolt hole pattern. Then, I would have tapped holes in the fixture plate (which is just a scrap of aluminum I use for these sorts of projects) and bolted the material down. The only potential problem with that is that the bolts could mark the surface on the parts. I decided instead to put bolts into the material that would be cut away during machining.

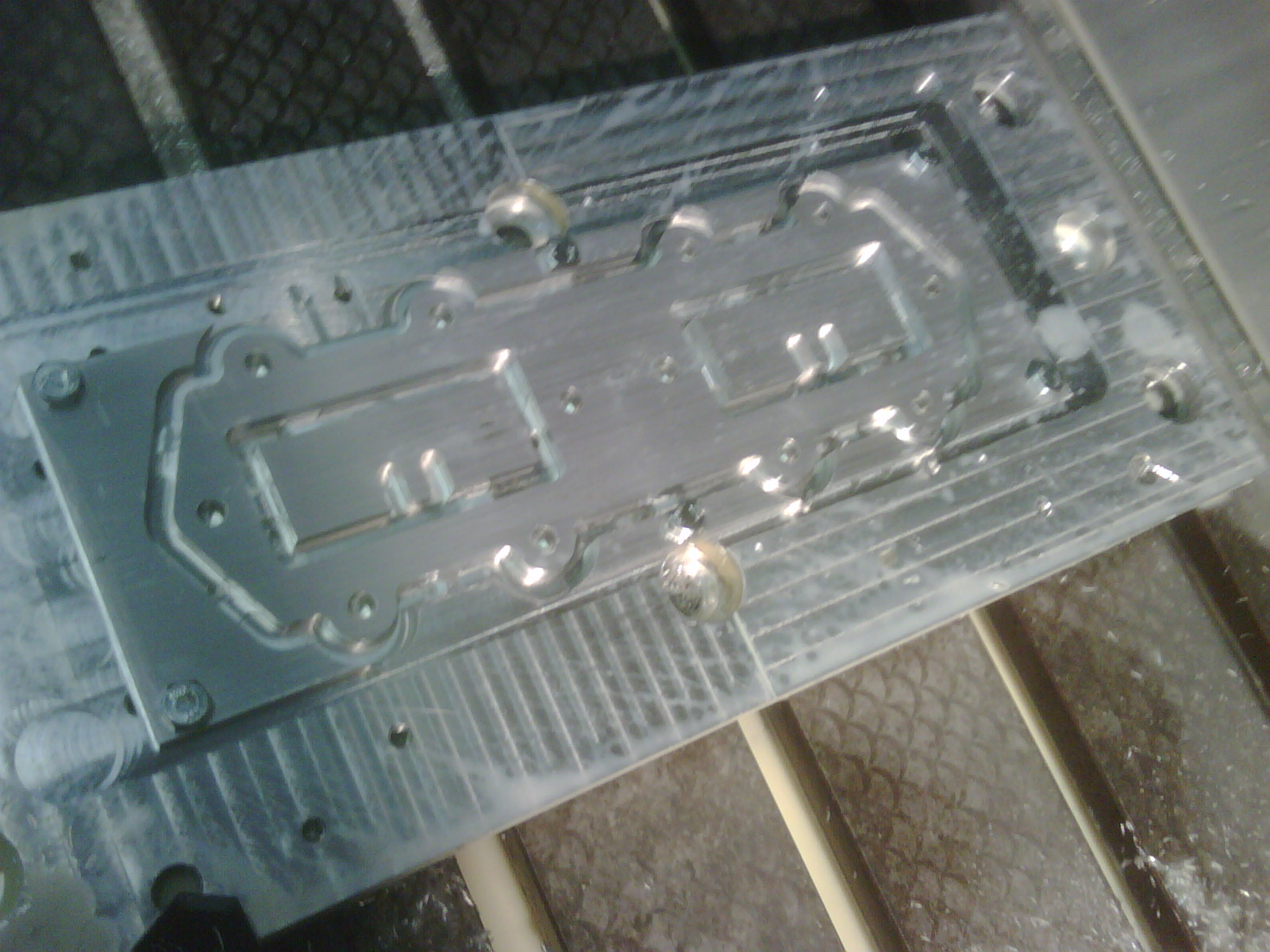

By not using the bolt holes in the part, when I finished machining this job the part would not be held by anything. That is a great way to throw it through a safety shield and bust an endmill. Not good. I used a technique where the part would be held with thin tabs at intervals around the part. My CAM system has the ability to put those in automatically, but if you are manually programming or editing g-code, all you would need to do is pick a spot on the final depth and have the cutter jump up. In this case, I used .025 as a tab thickness, and half inch wide.

Notice that the part stays together with the remainder material even after I unbolt it.

You have to be careful when choosing your tabs; if they are too thin, they will break during machining and the part will move, possibly wrecking it or damaging something else. If they are too thick, it will be difficult to remove the part from the stock. It should be noted also that the endmill moving up the side of the part like that WILL leave a witness mark. In this case, it really didn’t matter. This could have been minimized by having the CNC make more passes around the part, and then a finish pass that only skimmed over the tabs. The machinist has to decide what’s important for those considerations; I chose speed.